Borescope Inspection Services

Properly inspecting your turbines can be a complicated task, especially if you need to disassemble the turbine. At Advanced Turbine Support, we take pride in providing our clients with a non-destructive evaluation process, otherwise known as borescope inspection services. Since there is less labor, time, and risk required for reassembling your turbine incorrectly, this type of services saves you money and potential heartache.

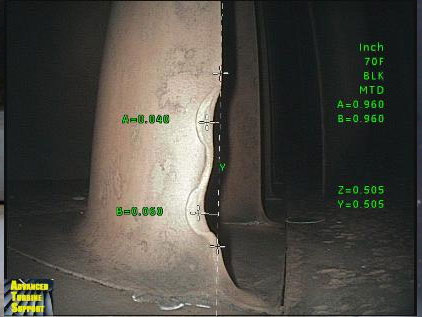

For this type of inspection, we use a borescope—hence the name. A borescope is a specialty instrument with a flexible tube, which contains a camera at the end. We use the tube to navigate tight spaces and windows throughout the turbine. Our borescope inspection services can reveal potential problems that may result in collateral damage. Using the highest quality equipment available, our experienced team provides comprehensive in-situ NDE borescope services with minimal unit disassembly.

Borescope inspections offer a variety of advantages other than not needing disassembly. Due to the flexibility of a borescope, you can reach greater depths of the turbine. This allows the inspector to complete a more thorough inspection of your turbine. The borescope produces high-quality photographs so that you can see even the smallest of imperfections.

Experienced inspectors who have been in the industry for years complete our NDE borescope inspection services. The brands and models we often work with include:

GE: Frames LM2500, LM5000, LM6000, LMS100, Frames:3, 5, 6, 7B, 7E, 7EA, 7F, 7FA, 7H, 9F, 9FA

Siemens: 171, 191, 251, 301, 501 D5, D5A, AA, F, G, SGT6-5000F, V84.2, V94.3

MHI: M501G

Alstom: GT-8, GT11, GT24

Pratt and Whitney: FT-4, FT-8

Rolls Royce: Avon 200, Trent 60

It is vital to have your turbines inspected on a regular basis. Proper borescope inspections services avail an opportunity to effectively plan for upcoming or emergent outages by documenting the overall condition of a unit. These inspections also provide information for mitigation plans to help eliminate the damage that could result in collateral damage, ultimately costing you more in the long run. We offer a number of services to keep your machines running at their best.

Contact us for more information about our professional borescope inspection services today!

Borescope inspections are relied upon for:

- Pre Commissioning

- Outage Planning

- Baseline Inspections

- Emergent Issues/ Forced Outages

- Semi Annual or Annual

- Time Sensitive Assessment

- Condition Based Maintenance

- Post Overhaul

From borescope inspections of gas turbines to steam turbines, Advanced Turbine Support has helped countless clients with their turbine inspection needs. Give yourself peace of mind, and schedule an appointment with our management team today.

Michael Hoogsteden

Director of Field Service

Scheduling, technical information, & inspection recommendations.

(727) 631-1467

Contact Michael

Brett Fuller

Field Service Manager

Report reviews and inspection recommendations.

(404) 313-0085

Contact Brett

Rod Shidler

President - Owner

Owner Information

(352) 302-2364

Contact Rod

Chris McGinley

Operations Manager

Purchase orders, estimates, business administration, contracts and billing.

(352) 231-5284

Contact Chris

Rick Ginder

CEO Advanced Turbine Support

Owner Information

(352) 262-5448

Contact Rick